Script. Var script = document.createElement("script") On that note, we’re selling this nozzle, with its limited wear warranty and all the above qualities, for only £22.50.If(!document.getElementById('paypal-smart-payment-script')) And with all the perks we've just mentioned, you might think a nozzle like this would be expensive this nozzle isn’t a status symbol- it’s a workhorse and the price reflects that.

E3D REVO NOZZLE X FREE

So we’re pleased to offer limited wear warranty if you do somehow manage to wear out your nozzle, just send it back to us and we’ll replace it, free of charge. 8 Nozzles) 172.23 E3D Revo Replacement Heater Core from 36. Best selling E3D Revo Voron from 85.78 E3D Revo Nozzle 29.89 E3D Revo ObXidian Nozzle 65.80 E3D Revo Six HotEnd Fully Loaded Kit 24v (.25. We’re confident that when used with any commercially available filaments this nozzle will essentially last indefinitely. We are proud to offer a wide selection of E3D Revo parts and accessories for your 3D printing needs. Coating abrasion is not covered by the limited wear warranty. E3D RapidChange Revo High Flow Brass Nozzle - 0.40mm 47 49 Coming Soon DiamondBack DiamondBack High Performance V6 Compatible Volcano Nozzle - 1.75mm x 0.40mm 94 99 100.00 Add to Cart ChampionX DiamondBack High Performance M6 Volcano Nozzle Sampler - Pack of 3 259 99 287.

The use of wire brushes should also be avoided.

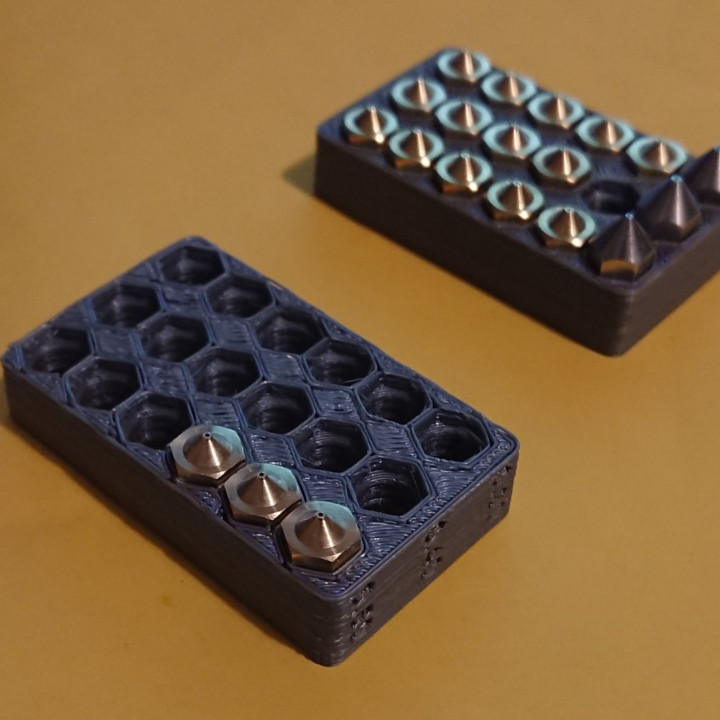

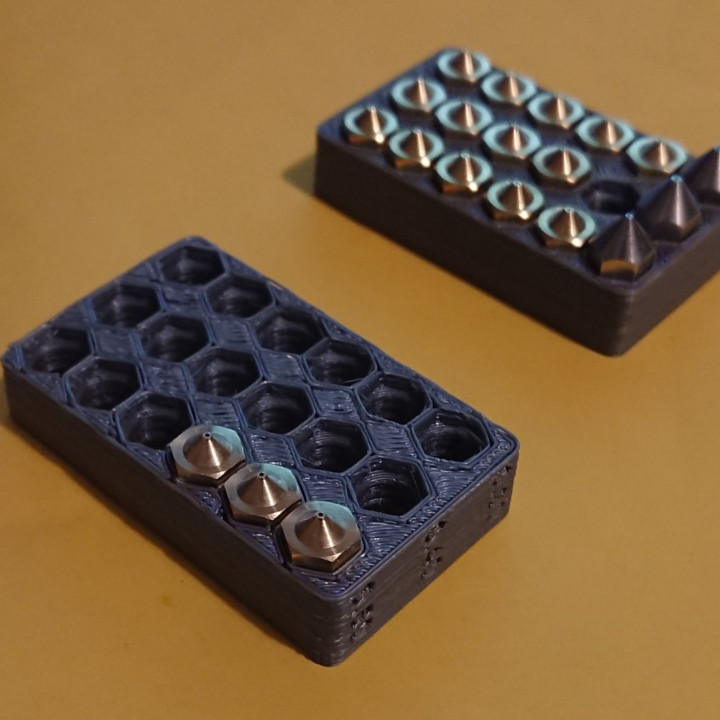

The coating will wear away from the nozzle tip-flat if used with abrasive material, but will still remain on the important ‘cone’ portion where material tends to build up. This coating reduces sticking of the material to the nozzle, but does not totally eliminate it (it’s a great step forward, but don’t expect a totally immaculately gleaming nozzle). Some cautionary notes to appropriately set expectations: Easier nozzle cleaning, what little material that does adhere is easily wiped away with a paper towel leaving a very clean nozzle. Slicker, smooth top solid layers with a glassy like finish as a result of the smooth laydown of material. Improved first layer reliability the slick coating has a reduced tendency to ‘drag’ material, particularly at sharp corners where tracks can peel up. Less build up, particularly of sticky and filled materials to the nozzle cone. To top all this off we’ve added our new ‘polyphobic’ nano-coating to the nozzle, hot molten polymer loves to stick to things, but we’ve found a new coating which much reduces this sticky build up - like an umbrella sheds water this coating prevents polymer wetting and adhering to the nozzle surface. We believe that our tool-steel and nickel coating provides a fantastic balance of cost and wear resistance. This causes poor flow response, high back-pressure, and starvation of extrusion.īy going with a one-piece all-machined construction we were able to use our existing manufacturing processes to create our carefully tuned internal geometry, which provides fantastic flow response and keeps the exact same geometry and compatibility as the rest of the E3D ecosystem. The second, and more troubling problem is that the construction of these insert-nozzles results in a sub-optimal internal geometry which restricts flow due to an internal ‘step’ in the polymer flow path. We strongly considered insert type nozzles with carbide or jewel tips, however these have two main issues, one is complexity/cost of the inserts and the process to precisely assemble the parts which results in the very high costs of these nozzles. To further increase the hardness and smoothness we added a layer of hard, slick nickel plating. So we set about to create a ‘no compromises’ nozzle and by using a special alloy of tool steel we were able to create a nozzle which is superbly hard, but also maintains this hardness to high temperatures without softening. Also, it flattens the layers, making them more squished. And there is more brass material around the terminal part, making it more resistant to abrasion and wear. I have noticed that the terminal part is more flattened around the hole.

Plated copper nozzles easily cope with these insane temperatures, but lack the abrasion resistance required to resist carbon fibre. The print quality for these nozzles is very similar to the V6 ones. Normally for abrasive filaments loaded with carbon-fibre we would use a hardened steel nozzle, however the extreme temperatures would cause the hardened steel to temper and soften - loosing it’s abrasion resistance.

We were printing large amounts of carbon fibre reinforced PEEK, at a temperature of 450C. The nozzle actually came into being very organically. High hardness, high temperature, and with a ‘polyphobic’ coating: a nozzle you will never have to change - a jack of all trades. Marketing gimmicks aside, this nozzle basically has it all: it’s both abrasion and heat resistant and has what we’ve dubbed a ‘polyphobic’ coating for cleaner prints and a cleaner nozzle. A next generation nozzle - one that can handle it all.

0 kommentar(er)

0 kommentar(er)